We are the global service provider for Functional Textile Auxiliaries.

About Us

— Jindong Technology Co., Ltd.

Jin Dong Technology is a comprehensive enterprise integrating product R&D, production, sales, and service. Its main products include energy-saving low-temperature pretreatment series, bio-enzyme preparation series, color-fixing series, ointment series, silicone oil series, and various high-concentration products.

The company has obtained OEK-TEX ZDHC Level 3 certification, “GTOS-ECO Product Certification,” ISO 9001 Quality Management System Certification, and “3AAA Measurement Management System Certification.” It has been recognized as a “Guangdong Province High-Tech Enterprise” and a “Guangdong Province Specialized, Refined, Unique, and New SME,” and is a member unit of the Guangdong Textile Auxiliary Industry Association. We have always adhered to the brand core value of “quality first, innovation for the future” and the business philosophy of “working together to create, sharing results, fearless of challenges, and continuously moving forward.” We strive to build a platform for development with employees, customers, and industry peers through continuous effort and innovation.

Experience

Decade of Textile Specialization

Area

Eco-Certified Production Base

Type

Product Variants

Global

Global coverage of countries

● Our philosophy

Main Product Situation

To better meet the market demands and satisfy customer needs, the company has established offices and corresponding marketing teams in Guangdong, Zhejiang, Jiangsu, Shandong, Fujian, and Jiangxi, and is dedicated to providing high-quality service support to all customers.

In order to better adapt to the market and meet the needs of customers, the company has established offices and corresponding marketing teams in Guangdong, Zhejiang, Jiangsu, Shandong, Fujian, Jiangxi and other places, and is dedicated to providing high-quality service support to all customers.

Pretreatment Additives

Pretreatment mainly includes penetrants, degreasing agents, refining agents, detergents, water softeners, chelating dispersants, etc.

Dyeing Auxiliaries

The main types include detergent for washing and rinsing, anti-stain detergent for washing and rinsing, leveling agent, fixation agent, low-temperature detergent for washing and rinsing, dispersant, and acid-based fixation agent, etc.

Texture-Enhancing Additives

Mainly include various types of silicone oils (hydrophilic soft and smooth silicone oils, smoothers), softeners, and foaming agents.

Function Enhancing Agent

Mainly include functional finishing products such as waterproofing agents, anti-static finishing agents, and antibacterial agents.

Denim Dyeing and Water Washing Additives

These mainly include desizing agents, softening agents, and fixation agents, which are suitable for denim products.

Enterprise Development Prospects and Outlook

General Situation of the Industry in Which the Enterprise Operates

In the future, as our country's economy continues to develop and the living standards and consumption capacity gradually increase, the demand for dyeing and finishing chemicals and textile printing and dyeing auxiliaries in the textile printing and dyeing industry will continue to grow, and the quantity entering the international market will also keep increasing. The demand for textile printing and dyeing auxiliaries in the textile printing and dyeing industry will continue to rise. China is currently the world's largest producer, consumer and exporter of textiles, and the consumption level of textile printing and dyeing auxiliaries per unit is still relatively low. The stable development of China's textile printing and dyeing industry will surely provide excellent opportunities for the development of the textile printing and dyeing auxiliaries industry. Currently, our company's production scale can rank among the top five in Guangdong, with a large output space and huge industry market prospects.

Characteristics of the Enterprise

○ Diversify the products, continuously optimize the existing ones, enhance the cost-effectiveness of the products, and continuously improve the product range. Develop new products and new processes in accordance with customer and market changes.

○ Provide timely and effective technical services. Different products are handled by specialized technicians. Provide timely services to customers and solve their problems. Offer customers the optimal production process and the most cost-effective products.

○ Have a mature technical team. Continuously learn and improve their professional skills. Participate in relevant dyeing auxiliaries associations multiple times each year to exchange and learn with peers, expand new ideas and concepts.

○ Implement standardized production management. Strictly follow safety production standards, standardize product production, and standardize production processes and techniques.

○ Segment sales areas. Expand business through both online and offline channels, and organize learning on sales techniques to enhance product promotion skills and techniques.

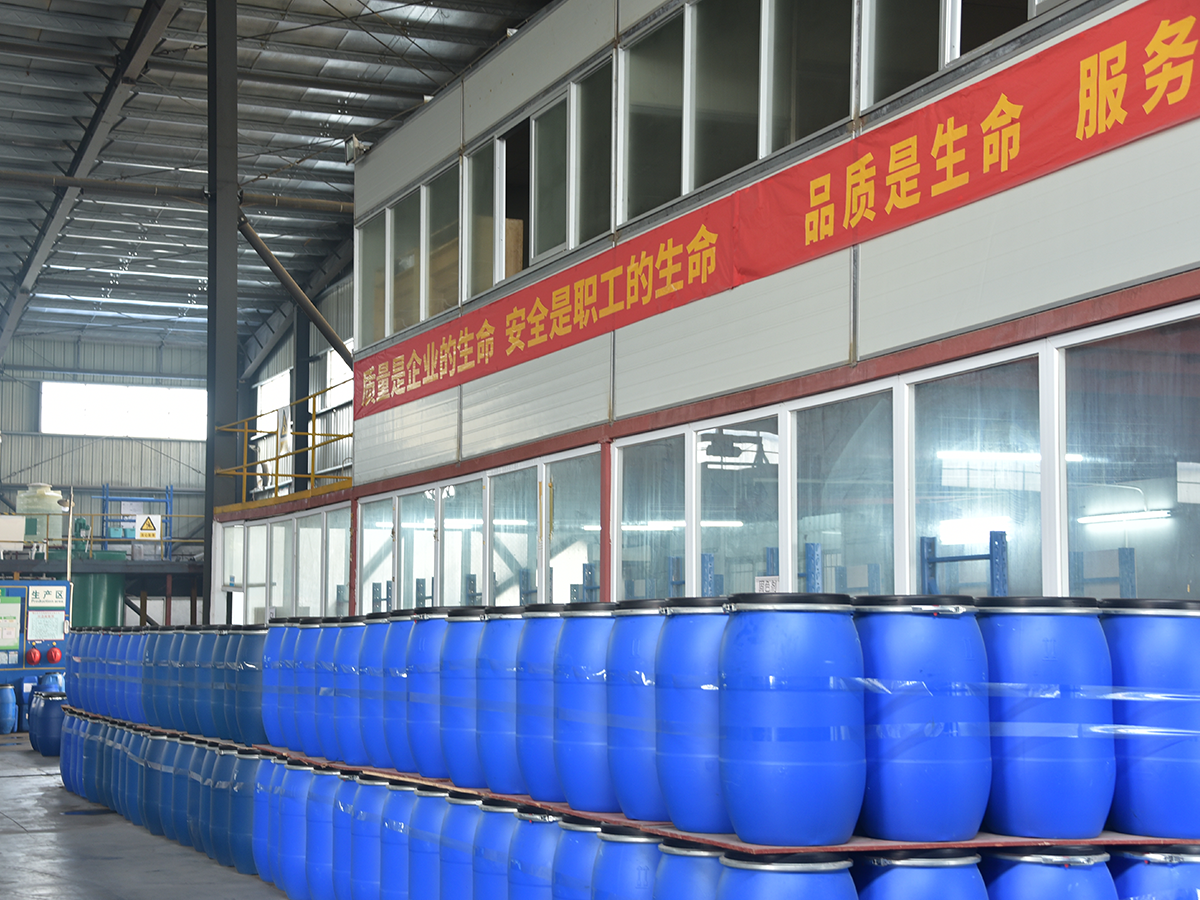

Production Workshop

Production Workshop

Production Workshop

Production Workshop

Enterprise Strategic Development Goals

At present, the demand for additives in the national market is high. Our company currently has ample production space for the supporting equipment. It is expected that the sales volume will exceed 100 million yuan in the next three years. The planning will mainly focus on the following aspects:

Continuously improving and optimizing the product types.

Enhance product technology to ensure the quality of product production, improve the cost-performance ratio of the products, and provide customers with high-quality products.

The sales market is continuously expanding, expand business areas, strengthen product promotion efforts online, and understand customers' actual needs offline.

The technical service level is constantly improving, maintain close contact and cooperation with customers, and communicate product situations in a timely manner.