Products Details

Low-Temperature Refining Agent

Category:

Parameters

This low-temperature refining agent has strong oil removal and penetration refining effects, and has excellent removal capabilities for lignin, ash, and cotton seed shells in cotton fibers.

1. The combined treatment of the two ensures the whiteness and brightness of bleached fabric bases, providing a good guarantee for the vividness of dyeing and coloring as well as the dyeing rate.

2. As it is treated at 85℃, the heating time is shortened, the steam usage is reduced, especially for certain factories with insufficient steam supply, it can effectively complete the pre-treatment process before production quickly, facilitating production operations.

3. As it is treated at 85℃, for varieties prone to creasing, it avoids the creasing stage during temperature rise and drop, and controls the creasing easily within the range of 85℃ - 60℃, significantly reducing the chance of creasing.

4. The low-temperature 85℃ pre-treatment for products containing spandex, under mild wet heat conditions, the strength of spandex does not decrease significantly, and the overall strength of the fabric is guaranteed. Compared with the conventional high-temperature 100℃ * 60min process, it can maintain an effect of reducing strength by 30-50N.

5. The low-temperature 85℃ pre-treatment has a mild production condition, short process time, and reduces the loss of cotton fibers during production processing, facilitating the guarantee of a low loss rate of the product during the processing.

Product Description

Pre-treatment process plan

In response to the current trend of energy conservation and emission reduction in environmental protection, in order to further improve and optimize the pre-treatment processing scheme of cellulose fibers, especially in the processing of T/C, CVC cotton and other products containing spandex, considering factors such as the significant decrease in product burst strength due to the needle structure of the product and the wet-heat strength reduction of the spandex fibers, the 85°C pre-treatment and bleaching process with low-temperature scouring agent is implemented to ensure the whiteness and luster of the product while shortening the processing time, reducing the chance of strength decline, creases and scratches, etc. The specific process is as follows:

1. Dark-colored varieties:

Sodium hydroxide 1.0%

Low-temperature refining agent 2.0%

H2O2 (27.5%) 6-8%

Process conditions: 85°C * 60 minutes

2. Light and bright-colored varieties:

Sodium hydroxide 1.0%

Low-temperature refining agent 2.0%

H2O2 (27.5%) 8-10%

Process conditions: 85°C * 60 minutes

3. White varieties:

Sodium hydroxide 1.0% (the specific dosage is adjusted according to the whiteness requirements)

Low-temperature refining agent 2.0%

H2O2 (27.5%) 12%

Process conditions: 85°C * 60 minutes

Note: The dosage of other additives should be calculated based on the actual bath ratio; when the bath ratio is less than 8, the dosage of additives should be calculated according to OWF; when the bath ratio is 8 or above, the dosage of additives can be calculated based on concentration in G/L. Specific adjustments can be made based on the actual application effect of the bulk goods.

Product Advantages

This low-temperature refining agent has strong oil removal and penetration refining effects, and has excellent removal capabilities for lignin, ash, and cotton seed shells in cotton fibers.

1. The combined treatment of the two ensures the whiteness and brightness of bleached fabric bases, providing a good guarantee for the vividness of dyeing and coloring as well as the dyeing rate.

2. As it is treated at 85℃, the heating time is shortened, the steam usage is reduced, especially for certain factories with insufficient steam supply, it can effectively complete the pre-treatment process before production quickly, facilitating production operations.

3. As it is treated at 85℃, for varieties prone to creasing, it avoids the creasing stage during temperature rise and drop, and controls the creasing easily within the range of 85℃ - 60℃, significantly reducing the chance of creasing.

4. The low-temperature 85℃ pre-treatment for products containing spandex, under mild wet heat conditions, the strength of spandex does not decrease significantly, and the overall strength of the fabric is guaranteed. Compared with the conventional high-temperature 100℃ * 60min process, it can maintain an effect of reducing strength by 30-50N.

5. The low-temperature 85℃ pre-treatment has a mild production condition, short process time, and reduces the loss of cotton fibers during production processing, facilitating the guarantee of a low loss rate of the product during the processing.

Relevant Index Testing

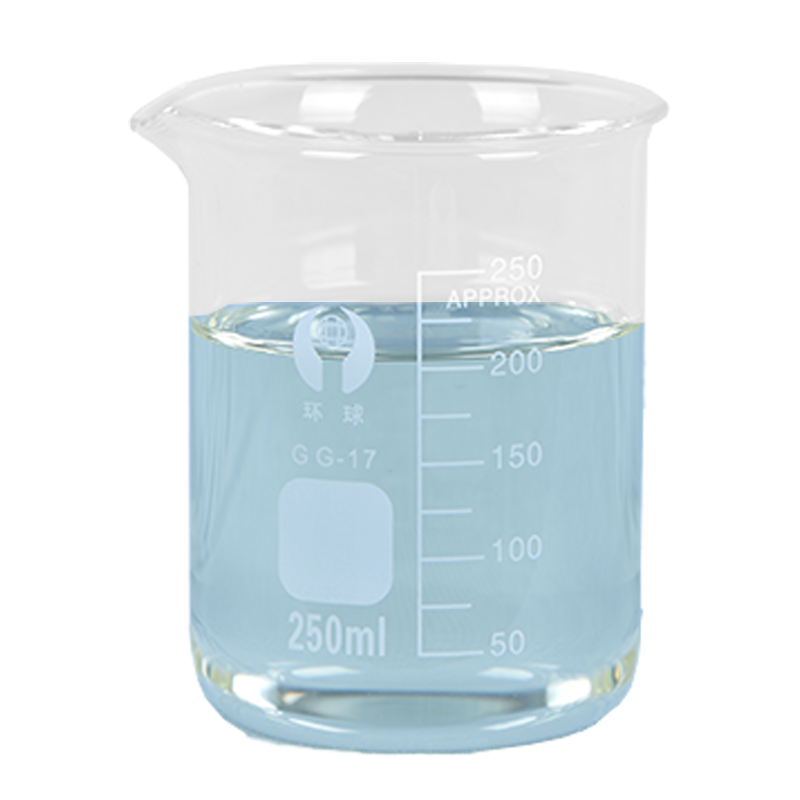

Appearance | PH value | solubleness | ionicity | Foaming property (room temperature-60℃-80℃) |

Blue transparent liquid  | 6 to 71% aqueous solution | soluble in water | Anionic/nonionic | 10s

|

Follow-up Situation of Bulk goods

Follow-up on the test bulk: Compared with the traditional process, the low-temperature refining agent has advantages in both whiteness and roughness.

| Follow-up project: Low-temperature refining agent | |||||||||||

| Machine:Three-skill water flow tank Number:P11009089 Date: 2021.10.12 | |||||||||||

| Fabric type: Ribbed vertical striped cotton hoodie frame | Colour: White | Weight: 20 pieces, 500KG | Bath ratio 1:10 | ||||||||

Types | Mobile machine parameters | Productive process | |||||||||

Main pump | 70 | Additives | normal | ||||||||

Turbine | 28 | Heating up | normal | ||||||||

Nozzle | Heating rate | 2 | |||||||||

Plant water l evel | 4000 | Insulation time | 60 | ||||||||

Shutdown water level | 5000 | Insulation pH | 13.1 | ||||||||

factory formula | Original formula name | Original formula dosage (g/L) | Current formula name | Current formula dosage | |||||||

Sodium hydroxide | 3 | Low-temperature refining agent 1082 | 2% | ||||||||

Substitute alkali | 2 | caustic soda | 1g/l | ||||||||

Substitute alkali | 2 | Hydrogen peroxide | 10g/l | ||||||||

Hydrogen peroxide | 10 | ||||||||||

manufacturing technique | 98℃*60min | 85℃*60min | |||||||||

Breed | Disorderly flowers | Vertical stripes | Cotton hoodie rack | Ribbed fabric | Disorderly flowers | Vertical stripes | Cotton hoodie rack | Ribbed fabric | |||

White value | 82.5 | 81.3 | 82.2 | 83.4 | 84.7 | 82.2 | 83.6 | 85.4 | |||

Hairiness coefficient cm | 13.7 | 14.0 | 15.5 | 14.1 | 14.5 | 14.7 | 17.5 | 15.3 | |||

Tear strength at the top | 307 | 280 | 315 | 354 | 315 | 282 | 344 | 388 | |||

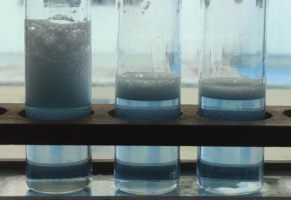

Boil the fabric sample at a low temperature |  | ||||||||||

Gross efficiency situation |  |  |  |  | |||||||

Follow-up project: Low-temperature refining agent | |||||||

Machine: Deyijia H7 Cylinder Number: H211000463 Date: October 26, 2021 | |||||||

Fabric type: Double hoodie | Color/Shade: Forest | Number/weight: 20 pieces, 484.2KG | Bath ratio1:6 | ||||

type | Mobile machine parameters | productive process | |||||

Main pump | 70 | Additives | normal | ||||

Turbine shaft | 160 | Heating up | |||||

Nozzle | 1#65 | Heating rate | 2 | ||||

Running water level | 2000 | Insulation time | 60 | ||||

Shutting-down water level | 2900 | Insulation pH | 13.2 | ||||

factory formula | Original formula name | The original formula dosage is g/L | Current formula name | Current formula dosage | |||

Non-ionic penetrant | 0.7 | Low-temperature refining agent 1082 | 2% | ||||

Caustic soda | 0.8 | Caustic soda | 1.5g/l | ||||

Refining enzyme | 1.5 | Hydrogen peroxide | 4g/l | ||||

Refining penetrant | 1 | ||||||

Hydrogen peroxide | 4 | ||||||

Production process | 98℃*60min | 85℃*60min | |||||

White value | 82 | 85 | |||||

Yarn fineness (cm) | 13.5 | 14.2 | |||||

Dyeing fabric sample |

| ||||||

Follow-up project: Low-temperature refining agent | |||||

Machine: Deyijia H7 Cylinder Number: H211000395 Date: October 22, 2021 | |||||

Fabric type: Smooth cotton sanitary ware | Color/Color Code: Dark gray | Number/weight: 20 pieces, 483.5KG | Bath Ratio 1:6 | ||

Type | Production line | machine parameters | |||

Main pump | 70 | Additives | Normal | ||

Turbine shaft | 160 | Temperature rise | Normal | ||

Nozzle | 1#65 | Temperature rise rate | 2 | ||

Running water level | 2000 | Insulation time | 60 | ||

Shutting-down water level | 2900 | Insulation pH | 13.1 | ||

factory formula | Original formula name | Original formula dosage g/L | Current formula name | Current formula dosage | |

Non-ionic penetrant | 0.7 | Low-temperature refining agent 1082 | 2% | ||

Caustic soda | 0.8 | Caustic soda | 1g/l | ||

Refining enzyme | 1.5 | Hydrogen peroxide | 4g/l | ||

Refining penetrant Hydrogen peroxide | 1 | ||||

Original formula name | 4 | ||||

Production process | 98℃*60min | 85℃*60min | |||

White value | 83.2 | 86.5 | |||

Finishing efficiency cm | 12.8 | 14.1 | |||

Washing sample fabric |  | ||||

Follow-up of Subsequent Trials

Bath ratio and dosage reference test

Sequence | Weight of the cloth | bath ratio | 1082 Dosage | NAOH Dosage | H2O2 Dosage |

Scheme 1 | 20G | 1:10 | 2G/L | 1G/L | 10G/L |

Scheme 2 | 20G | 1:5 | 2G/L | 1G/L | 10G/L |

Scheme 3 | 20G | 1:5 | 2% | 1G/L | 10G/L |

Scheme 4 | 20G | 1:5 | 2% | 1% | 10% |

Immersion method: 85℃ for 60 minutes, then 135℃ for final drying.

Name | Scheme 1 | Scheme 2 | Scheme 3 | Scheme 4 |

Illustration |

|

|

|

|

Scheme 4 | Scheme 4 | Scheme 4 | Scheme 4 | Scheme 4 |

White value | 86.4 | 82.4 | 84.7 | 87.0 |

Scheme 4 | Scheme 4 | Scheme 4 | Scheme 4 | Scheme 4 |

30min mount | 14.9cm | 11.2cm | 14.8cm | 16.2cm |

Tag list: Low-Temperature Refining Agent

About Jin Dong

Jindong Technology (Foshan) Co., Ltd.

Jindong Technology (Foshan) Co., Ltd. was established in August 2013, initially mainly engaged in textiles Production of raw materials for weaving auxiliaries and daily chemical series products. Since 2016, I have been an independent student in the new factory area. It is in operation and production, covering an area of approximately 20 r. It has complete environmental assessment and safety inspection procedures and no flammable or explosive hazards Insurance products, with an annual output value scale of up to 100 million yuan, in 2019. It was consecutively rated as a provincial product in 2022 High-tech enterprise, it was rated as a provincial specialized, refined, distinctive and innovative enterprise in December 2022.

✅ 35+ Patents, Strong Innovation:

35 utility models + 2 invention patents (pending). Continuous tech upgrades ensure high-performing products.

✅ One-Stop Solutions = Save Cost & Time:

R&D, production, tech support all-in-one service to cut costs & boost efficiency.

✅ Gov-Certified Quality + Digital Control:

Provincial-certified Hightech & "Specialized" company. ERP system ensures standardized quality.

✅ 6-Province Local Teams = Fast Support:

On-site teams in 6 provinces. Quick customized solutions via online/offline channels.

Frequently Asked Questions

Which industries use your products?

What demonstrates its technical capabilities?

How has the company evolved?

What certifications does the company hold?

What are the key products?

When was the company founded? What is its core business?

Category:

Parameters

This low-temperature refining agent has strong oil removal and penetration refining effects, and has excellent removal capabilities for lignin, ash, and cotton seed shells in cotton fibers.

1. The combined treatment of the two ensures the whiteness and brightness of bleached fabric bases, providing a good guarantee for the vividness of dyeing and coloring as well as the dyeing rate.

2. As it is treated at 85℃, the heating time is shortened, the steam usage is reduced, especially for certain factories with insufficient steam supply, it can effectively complete the pre-treatment process before production quickly, facilitating production operations.

3. As it is treated at 85℃, for varieties prone to creasing, it avoids the creasing stage during temperature rise and drop, and controls the creasing easily within the range of 85℃ - 60℃, significantly reducing the chance of creasing.

4. The low-temperature 85℃ pre-treatment for products containing spandex, under mild wet heat conditions, the strength of spandex does not decrease significantly, and the overall strength of the fabric is guaranteed. Compared with the conventional high-temperature 100℃ * 60min process, it can maintain an effect of reducing strength by 30-50N.

5. The low-temperature 85℃ pre-treatment has a mild production condition, short process time, and reduces the loss of cotton fibers during production processing, facilitating the guarantee of a low loss rate of the product during the processing.