Products Details

Fluffy Thickening Agent

Category:

Parameters

1. Fluffy: This product has the characteristics of low foaming, anti-static, and softness, which can enhance the rebound property of the fabric.

2. Hydrophilic: The hair-raising effect of this product is good, and its water absorption is excellent. The finished fabric has the characteristic of absorbing sweat.

3. Less yellowing: Low yellowing, with little impact on the color and light of the fabric.

4. Can replace all softeners, convenient for chemical processing, and environmentally friendly.

5. This product has good stability and compatibility.

Product Description

Main Components

Polyvalent alcohol surfactant inducing agent

Physical Indicators

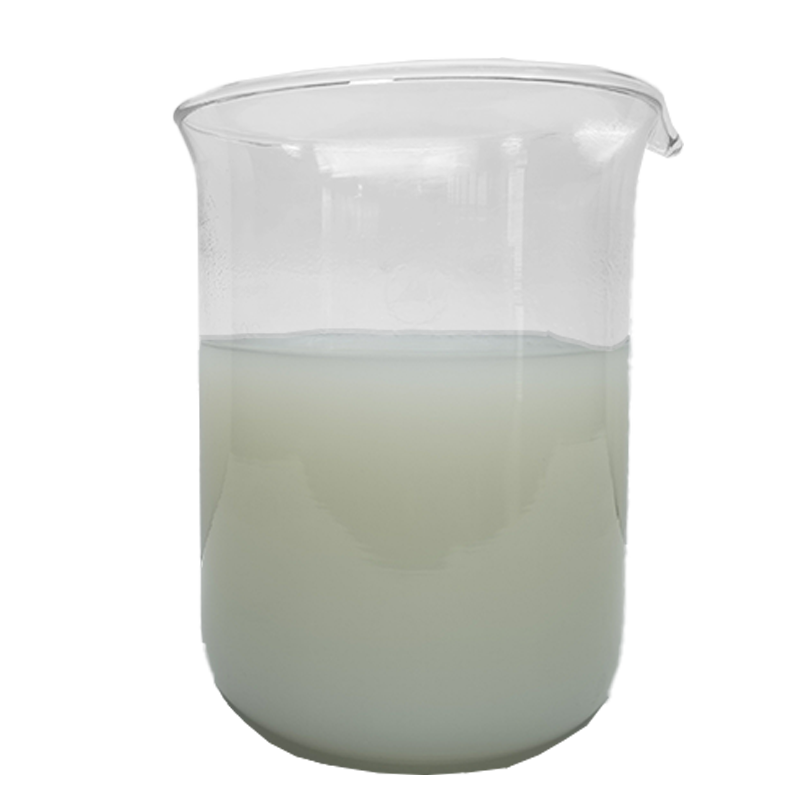

Appearance: White emulsion

Ionic Nature: Weak cationic

pH Value: 6-7 (1% aqueous solution)

Performance Characteristics

1. Fluffy: This product has the characteristics of low foaming, anti-static, and softness, which can enhance the rebound property of the fabric.

2. Hydrophilic: The hair-raising effect of this product is good, and its water absorption is excellent. The finished fabric has the characteristic of absorbing sweat.

3. Less yellowing: Low yellowing, with little impact on the color and light of the fabric.

4. Can replace all softeners, convenient for chemical processing, and environmentally friendly.

5. This product has good stability and compatibility.

Application Scope

This product is suitable for cotton and synthetic cotton, synthetic fibers, T/C blended fabrics, etc. It can replace all films and is convenient for processing.

Usage Instructions

Before using this highly concentrated product, dilute it to the same concentration as the soft sheet. It is recommended to dilute 1 part to 10-15-20 parts before use.

The amount used should be appropriate according to the type of fiber, application, and the desired softness of the texture.

1. After dyeing (dipping method)

2. 20-50g/L, dip and roll at 40-50℃ for 20-30 minutes

2. During setting (wet spinning method)

Wet spin and roll at 20-50g/L for setting and then dry it

The specific amount should be adjusted according to customer requirements!

Storage and Transportation

1. Use polyethylene plastic drums, lined with plastic bags, each containing 110KG.

2. Store in a cool, dry and well-ventilated warehouse; shelf life is 6 months.

Application Experiment Report

Experimental Department: Technology Department

Experimental Objective (Plan): To compare the texture and feel of our company's hydrophilic fluffy ointment 5041 with those of commonly used soft sheets/spheres on the market.

Test Results:

1. Background

Compare the effects of our company's hydrophilic fluffy ointment 5041 with those of commonly used soft sheets on the market, and test for yellowing, hydrophilicity, and texture.

2. Experimental Materials and Process Flow

2.1 Materials

2.1.1 Knitted semi-washed pure cotton fabric

2.1.2 Knitted whitening cotton fabric

2.1.3 Knitted red pure cotton sweatshirt fabric

2.1.3 Commonly used soft sheets on the market

Cationic TF soft beads/soft sheets, LS soft sheets, GB soft sheets, KSD soft sheets, DS soft sheets

2.2 Test Instruments and Equipment

P-AO pneumatic small rolling machine, 101A-2 type oven, R-3 type setting machine

AS-12 constant temperature small sample machine

2.3 Process

2.3.1 Impregnation Method

Immersion method: 45℃ * 20 minutes, then dry at 170℃ * 100 seconds

Dosage: All samples were diluted 15 times, and the usage amount was 3%

Test for hydrophilicity, yellowing, and texture.

3. Test Conditions

3.1 White Degree Test Conditions (Average value is calculated based on 4 tests)

Product Name | Semi-washed Pure Cotton Railing Fabric | Whitened Plain Weave Fabric |

Non-handling Fabric | 79 | 132 |

Hydrophilic Fluffy Soft Sheet 5041 | 78.5 | 131.6 |

TF Cationic Film | 77.8 | 130.6 |

LS Cationic Film | 78.2 | 131.5 |

GB Cationic Film | 77.6 | 130.8 |

DS Cationic Film | 78.1 | 131.3 |

KSD Cationic Film | 78.4 | 131.2 |

TF Cationic Soft Beads | 78.6 | 131.5 |

Summary: Compared with the commonly used soft films/soft beads in the market, our hydrophilic fluffy ointment 5041 has a relatively minor impact on whiteness.

3.2. Hydrophilic Condition (It has a certain influence on the hydrophilicity of the fabric before it becomes too soft)

Product Name | 40S Whitening Cotton Knitted Fabric (Hydrophilic Time s) | Red hoodie fabric (Hydrophilic time s) |

Non-touching fabric | 1 | 1-2 |

Hydrophilic fluffy ointment 5041 | 1 | 2 |

TF cationic film | 1-2 | 2-3 |

LS cationic film | 1-2 | 2-3 |

GB cationic film | 1-2 | 2-3 |

DS cationic film | 1-2 | 2-3 |

KSD cationic film | 1-2 | 2-3 |

TF cationic bead | 1-2 | 2-3 |

Summary: Our hydrophilic fluffy ointment 5041 has basically no effect on the hydrophilicity of cotton fabrics.

3.3 Sensory Research

Our hydrophilic fluffy ointment 5041, after softening, has a soft texture and a fluffy appearance. Its softness and fluffiness can achieve the same effect as the commonly used soft sheets or soft beads in the market.

For specific details, please refer to the touch test section.

3.4 Application Features

3.4.1 The process is convenient; materials can be directly weighed and used without the need for heating or dilution.

3.4.2 It is suitable for various fibers and their blended fabrics.

3.4.3 During reconditioning, there is no need to soften; simply boiling in hot water is sufficient.

3.4.4 It has good compatibility and can be used with any non-ionic and cationic products.

4. Summary

Based on the comparison of the tests, it can be concluded that:

4.1 Compared with the commonly used soft films/soft beads on the market, our hydrophilic fluffy ointment 5041 has a relatively small impact on whiteness.

4.2 Our hydrophilic fluffy ointment 5041 basically does not affect the hydrophilicity of cotton fabrics.

4.3 After becoming too soft, the texture, fluffiness, and softness of our hydrophilic fluffy ointment 5041 can match the texture effects of commonly used soft films on the market.

4.4 It has a wide application range, is easy to operate, and has strong applicability.

Tag list: Fluffy Thickening Agent

About Jin Dong

Jindong Technology (Foshan) Co., Ltd.

Jindong Technology (Foshan) Co., Ltd. was established in August 2013, initially mainly engaged in textiles Production of raw materials for weaving auxiliaries and daily chemical series products. Since 2016, I have been an independent student in the new factory area. It is in operation and production, covering an area of approximately 20 r. It has complete environmental assessment and safety inspection procedures and no flammable or explosive hazards Insurance products, with an annual output value scale of up to 100 million yuan, in 2019. It was consecutively rated as a provincial product in 2022 High-tech enterprise, it was rated as a provincial specialized, refined, distinctive and innovative enterprise in December 2022.

✅ 35+ Patents, Strong Innovation:

35 utility models + 2 invention patents (pending). Continuous tech upgrades ensure high-performing products.

✅ One-Stop Solutions = Save Cost & Time:

R&D, production, tech support all-in-one service to cut costs & boost efficiency.

✅ Gov-Certified Quality + Digital Control:

Provincial-certified Hightech & "Specialized" company. ERP system ensures standardized quality.

✅ 6-Province Local Teams = Fast Support:

On-site teams in 6 provinces. Quick customized solutions via online/offline channels.

Frequently Asked Questions

Which industries use your products?

What demonstrates its technical capabilities?

How has the company evolved?

What certifications does the company hold?

What are the key products?

When was the company founded? What is its core business?

Category:

Parameters

1. Fluffy: This product has the characteristics of low foaming, anti-static, and softness, which can enhance the rebound property of the fabric.

2. Hydrophilic: The hair-raising effect of this product is good, and its water absorption is excellent. The finished fabric has the characteristic of absorbing sweat.

3. Less yellowing: Low yellowing, with little impact on the color and light of the fabric.

4. Can replace all softeners, convenient for chemical processing, and environmentally friendly.

5. This product has good stability and compatibility.